Deacero 3M

Project Description

Client: Deacero Location: Ramos Arizpe, Coahuila, México Projects: Billet Warehouse, Water Treatmet Plant, Additives Structure (Chutes and Hoppers), Scrap Metal Warehouse, Fume Exhaust System, CCM structure, others. Year Completed: 2013 Engineering company: Danielli. After a great job done in the Deacero’s steel mill in Celaya, Durosa had the opportunity to work in the construction of Deacero’s newest steel mill Deacero 3M.

The Challenges

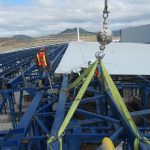

One of the biggest challenges we had in this project, was the fabrication and erection of the Fume Exhaust ducts. The size of the secondary duct was 7 meters in diameter and had to be installed at an approximate height of 50 meters, with the complexity of having very limited space to maneuver in the 300 ton cranes between the scrap metal warehouse and the billet warehouse. For start Durosa had to build an on site facility to bend roll the huge ducts as they where not transportable, so we roll bend them in site and made a very systematic plan for erecting each an every segment of the exhaust system.